TWIN SHAFT MIXER MAINTENANCE

TWIN SHAFT MIXER

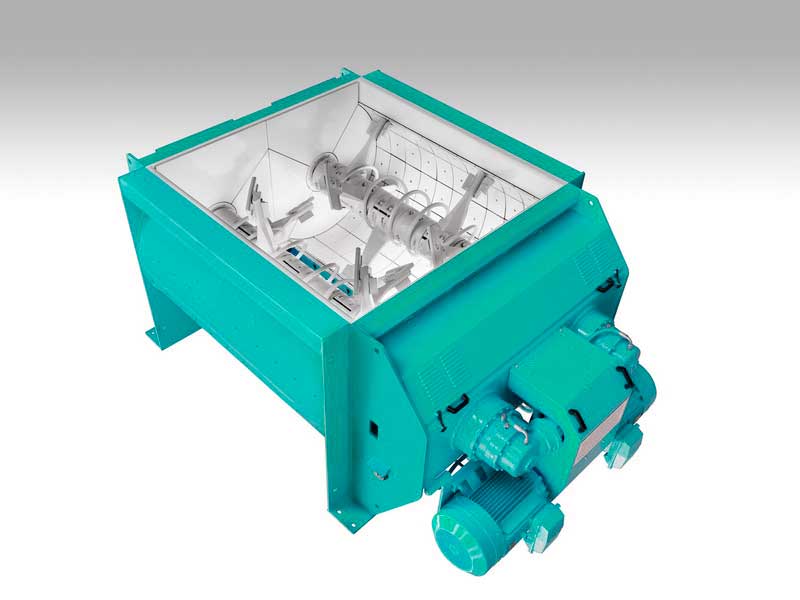

Twin shaft mixers implement mixing operation by 2 (two) shafts, which rotate in opposite directions synchronized and have mixing arms and pallets.Due to the opposition of the shafts; mixing arms and pallets prevent the low densed materials to float, as well as create maximum homogenity in a short period of time.

The actuation of the mixer shafts are made by two motors and two gearboxes.Each shaft is actuated by a group composed of the gearbox and the motor with belt and pulley.The mixer shafts work in a synchronized way, since the gearboxes are connected by a shaft.For safety; the gearbox, motor, belt and pulley system is covered by sheets.

The actuation of the mixer shafts are made by two motors and two gearboxes.Each shaft is actuated by a group composed of the gearbox and the motor with belt and pulley.The mixer shafts work in a synchronized way, since the gearboxes are connected by a shaft.For safety; the gearbox, motor, belt and pulley system is covered by sheets.

Mixer discharge cover is located at the bottom and in the middle, and it is actuated hydrolically.The discharge of concrete occurs very fastly, since the cover dimension is nearly as large as the mixer dimension. The contruction includes switches in order to control the open and closed positions of the mixer discharge cover.

The mixer shafts have been beared to the body by a group of gaskets and ball bearings.The mixer has been equipped with central automatic lubrication, in order to prevent the bearings from the grout overspilling the mixer and let them have a long iife.The lubrication is implemented by the central automatic lubrication system which is operated by the automation software.

There is a maintenance cover on the mixer for cleaning and maintenance.There also exists a safety switch on the maintenance cover which turns off the electrical power, when the cover is opened.There is an “emergency stop button” on the mixer for emergency cases.The operation of the system could be stopped by the button in case of emergency.

THREE IMPORTANT MAINTENANCE

1-LUBRICATiON

BE SURE THAT THE CENTRAL LUBRICATION PUMP WORKS PROPERLY. OTHERWISE MIXER MAY GET DAMAGED.

CHECK WHETHER THERE IS ANY LEAKAGE IN THE CONNECTION POINTS OF CENTRAL LUBRICATION TANK AND LUBRICATION SYSTEM? IF YOU DETECT ANY DECREASE OF LUBRICANT IN THE LUBRICATION TANK, THEN REFILL NEEDED AMOUNT. (6 LT)

2-ADJUSTMENT

STRETCH THE BELT BY THE BELT STRETCHING UNIT. CHECK THE TENSION EVERY DAY.

3-CLEANING

AT THE END OF EVERY WORKING DAY, MIXER SHOULD BE EMPTIED AFTER OPERATED BY FILLING IT WITH WATER AND GRAVEL.WASH NON-CLEANED PARTS OF THE MIXER WITH PRESSURIZED WATER.

NEVER DO IT

Never operate the mixer as loaded when it stopped with full of material inside it. In such cases, before operating the mixer, discharge the remaining material inside the mixer, by operating the hydraulic valve of the mixer discharge cover manually or opening the mixer discharge cover through automation system without starting the mixer. Start up the mixer, after discharged bulk of the material inside the mixer.

To open the mixer discharge cover manually, press one of the openingclosing buttons, which are located on the valve, by means of a thin screw driver. If it does not open, try the other one (One of the buttons is for opening the cover the other one is for closing the cover. To perform the manual opening-closing operation, press the buttons separately).

In case, the mixer runs as loaded, the following malfunctions may occur.

These are nonwarrantable; our company is not responsible for the malfunctions, which may occur due to misuse of the mixer.

- MIXER FUSES MAY BURN OUT.

- MIXER MOTOR MAY BURN.

- MIXER GEARBOXES MAY BE DAMAGED.

- MIXER BEARINGS AND MIXER ROLLERS MAY BE DAMAGED

- IF THE MIXER ROLLERS ARE DAMAGED THEN IT CAUSES THE MIXER SHAFT TO BREAK.